AUSTRALIA OPEN WIRE FED MULTI PASS OSCILLATING WELD HEAD

Open Wire Fed Multi Pass Oscillating Weld Head

- Multiple run capable including heavy wall thickness pipe.

- AVC – Arc voltage control retains the gap between the work piece and the tungsten. Adjustable during welding.

- Step Mode – Increment pulsing that ensures any miss matched edges within tolerance don’t get missed. Step mode also enables more penetration through better control of the arc.

- OVC – Oscillating side to side enabling weaving for caps and bigger gaps. If stringers are required this mode can be turned right down or off to accommodate.

- Root run, Fill and Cap class 1 capable. Adjustable during welding.

- I joint (no V prep) with no root gap with 6mm thickness and under. Speed up pipe fitting with this ability.

- Full adjustment and dynamic control due to hand controller while welding.

- Easy clamp on clamp off system with quick release lever.

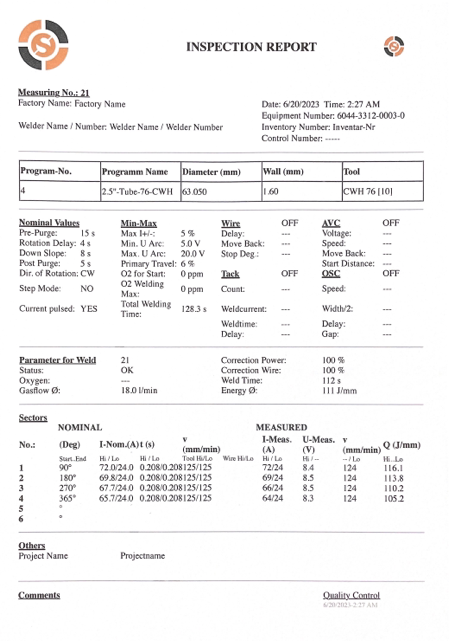

- Weld report recorded each pass for weld identification and weld procedure documentation (click on the report form below).

- Please see the manual below to see machine programme options and adjustments.

Cold wire feeders

The focus is on compactness and robustness

The robust cold wire feeders are characterized by their compactness. There are three different types to choose (CWF-1 – 1 kg wire spool, CWF-5 – 5 kg wire spool and CWF-15 – 15 kg wire spool). The suitcase can be closed and keeps the mechanism safe from dust, oil etc. The devices can be operated with the open weld heads OWH and the turn tables. Our machines can be operated lying or standing and are disposed with a 2- / 4-roll-gear for the cold wire feeding (Swiss Made).

CWF 1

The cold wire feeder CWF-1 can absorb sigmet-spools up to 1 kg maximum weight. A dust-proof and stabile suitcase keeps the mechanism and the wire safe from damage and corrosion.

Details:

- Dust-proof and robust suitcase, made for the industrial application

- 2-wheel-gear for the cold wire feeding

- Suitable for wire diameters 0,6 mm and 0,8 mm

- Inexpensive wire feeding hose mountable with a fast-click-system (without tools)

- Devices can be operated lying or standing

- Wire centering inside the case up to the wire feeding-bracket

Data:

- Electrical power supply: 24 V DC

- Dimensions L x W x H (mm): 115 x 250 x 210

- Weight without reel (kg): 1.5

CWF 5

The cold wire feeder CWF-5 can absorb sigmet-spools up to 5 kg maximum weight. A dust-proof and stabile suitcase keeps the mechanism and the wire safe from damage and corrosion.

Details:

- Dust-proof and robust suitcase, made for the industrial application

- 4-wheel-gear for the cold wire feeding, „Swiss Made“

- Suitable for wire diameters 0,8 mm and 1,0 mm

- Inexpensive wire feeding hose mountable with a fast-click-system (without tools)

- Engine versions with tachometer- and encoder-regulation possible (AMI, Polysoude)

- Devices can be operated lying or standing

- Wire centering inside the case up to the wire feeding-bracket

Data:

- Electrical power supply: 24 V DC

- Dimensions L x W x H (mm): 320 x 410 x 205

- Weight without reel (kg): 7.2

CWF 15

The cold wire feeder CWF-15 can absorb sigmet-spools up to 15 kg maximum weight. A dust-proof and stabile suitcase keeps the mechanism and the wire safe from damage and corrosion.

Details:

- Dust-proof and robust suitcase, made for the industrial application

- 4-wheel-gear for the cold wire feeding, „Swiss Made“

- Suitable for wire diameters 0.8 mm and 1.0 mm

- Inexpensive wire feeding hose mountable with a fast-click-system (without tools)

- Engine versions with tachometer- and encoder-regulation possible (AMI, Polysoude)

- Devices can be operated lying or standing

- Wire centering inside the case up to the wire feeding-bracket

Data:

- Electrical power supply: 24 V DC

- Dimensions L x W x H (mm): 450 x 510 x 230

- Weight (kg): 9.1